Industry 4.0 – Germany’s Smart production

It is probably one of the most dynamic economic trends in the global manufacturing industry: The “fourth industrial revolution” is expected to turn production processes upside down. For years, decision-makers and experts considered it a myth. Today Germany’s industrial heartland, North Rhine-Westphalia (NRW), is pushing its development forward. This opens up new opportunities for German and international investors.

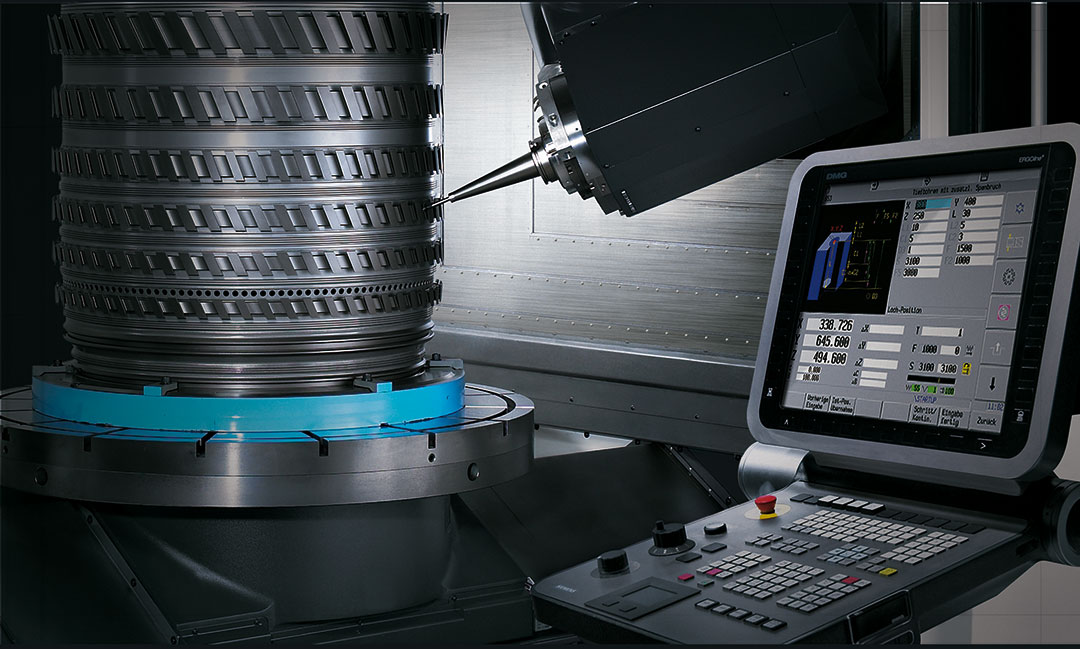

This evolutionary change involves modern ICT being incorporated into highly automated and networked production processes that are blurring the boundary between the real and the virtual worlds. The factories of the future are interoperable, modular, self-adapting, decentralized and work in real time – in short, they are smart factories. The workers control production processes via cyber-physical systems while the machines monitor themselves and communicate with each other to optimize production processes, the use of resources, logistics and maintenance work. Factories will no longer have boundaries: plants at different locations are connected in peer-to-peer networks. Suppliers, manufacturers and customers are brought closer together than ever before. The products are more individualized and linked with high-quality services to create innovative hybrid products.

As the world’s leading industry supplier – engineering and plant equipment are traditional strengths in the country’s economy – Germany wants to enhance its competitive edge. The German government is pushing Industry 4.0 with funds of around 200 million euros. At the same time, the big corporates and the thousands of German small and medium-sized entrepreneurs are investing in ICT to speed up their own development. According to the Experton Group their spending on Industry 4.0 R&D will rise in 2015 to 650 million euros. For the next ten years, German companies plan to invest around 10.9 billion euros in the evolution of Industry 4.0.

In particular, Germany’s industrial heartland, NRW, is supporting industry and science in pushing the development ahead. With new manufacturing processes, productivity can rise in some sectors by 30 percent. This could lead to around 15.6 billion euros of additional gross value for the state’s economy over the next ten years. It is therefore no surprise that many universities and research and development institutes in the region have successful basic research projects and are now aiming to transfer them to the industry.

Funded by the German Federal Ministry of Education and Research (BMBF), the Leading Edge Cluster “it’s OWL” in OstWestfalenLippe, which brings together a total of 174 partners, is particularly innovative in the development of intelligent technical systems. World market and technology leaders work here in cooperation with research institutions in 45 projects on intelligent products and manufacturing processes. The Detmold-based company Weidmüller, for example, has developed a self-correcting punching and bending machine, by means of which set-up times can be reduced by 20 percent while massively minimizing waste at the same time.

Potential for venture capitalists and investors

The predictability of delivery times, one of the biggest challenges in industrial manufacturing, can also be improved in the future by means of applications from NRW. Within the framework of the research project ProSense, for example, the Cluster of Excellence Integrative Production Technology for High-Wage Countries at RWTH Aachen University has developed a production control system based on a cyber-physical support system and intelligent sensors. This M2M communication enables companies to significantly improve their delivery performance and in this way substantially increase productivity.

The extent to which networking is changing the factory of tomorrow is illustrated by the Fraunhofer Institute for Material Flow and Logistics (IML) in Dortmund, one of the world’s largest logistics research institutes. A networked warehouse without conveyor belts has been developed here using swarm intelligence. Individual driving robots organize themselves, creating decentralized control of the material routes.

Basically, the intelligent networking of production processes requires the use of complex software. To this end, traditional mechanical and plant engineering has to collaborate intensively with specialists in the development of production software. This offers great potential for venture capitalists who can finance start-ups accordingly. In particular, the fast-growing spin-offs at universities with innovative product developments require financial partners. One example of these start-ups is the Düsseldorf-based company Cumulocity which has developed software that facilitates mobile communication between humans and machines on the Internet of Things. Via the Cumulocity platform, devices can be monitored and control worldwide via the Internet; this is where real and virtual reality actually merge. Here in particular there are ideal investment opportunities for companies offering solutions in this field with their products and services.

NRW as a pioneer in the key area of IT security

When it comes to communicative infrastructure, with the densest broadband coverage in any non-city federal state, North Rhine-Westphalia already provides the ideal conditions and continues to focus on the extensive expansion of high-speed networks with more than 100 megabits per second. But it is no longer just about speed, but also about security.

Data security requirements in this country are traditionally very high, and the state of NRW has once again devoted itself specifically to this topic: In order to ensure that every individual and every company retains sovereignty over their own data, North Rhine-Westphalia has assumed a pioneering role, as embodied by the world renowned Horst Görtz Institute (HGI) in Bochum. Overall, around 1,000 scientists in NRW alone are conducting research into how the encryption of data for corporate and home users can be improved.

But North Rhine-Westphalia has even more to offer. The state has also experienced and contributed to all the major industrial upheavals. This experience of change is a valuable cultural advantage heading into the fourth industrial age.